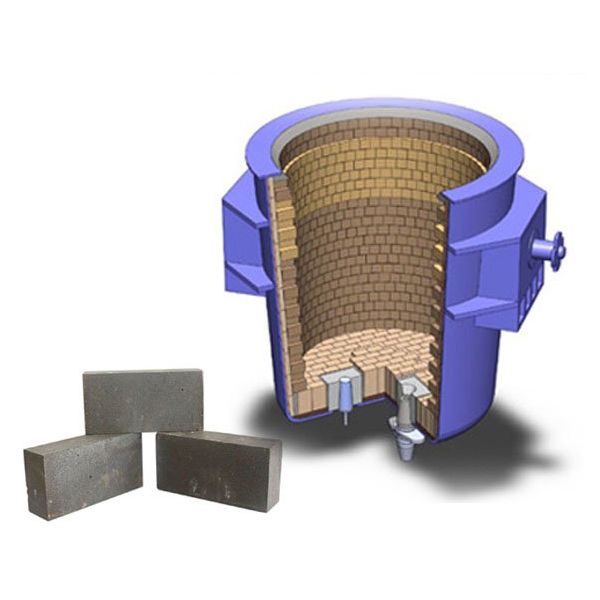

Furnaces are the place where the temperature is too high and items made are heated up at very high temperatures. Metals and glasses and many other items are heated up so much that they can meltdown so that they can be used in different ways.

For such temperature, high alumina bricks are used because they are very much resistant to corrosion in nature and are able to tolerate a high amount of temperature.

If you are looking for such bricks for any kind of furnace in your factory, then we can offer you the best options by now. We are also among the best high alumina bricks exporters in India and have been exporting our products to various other places such as UAE, UK, USA, Nigeria, and many others.